WE ARE PROBLEM SOLVERS

Continental's customer-driven approach has yielded flexible paint solutions for its clients with paint formulations that are adapted to meet specific and often complex coating requirements.

When designing a paint for a customer, it is standard for our chemists to create a series of formulation ladders to determine performance and cost parameters.

OEM PAINT CATEGORIES

WATER BASED - HIGH SOLIDS - 2K URETHANE

WATER BASED

- Custom Formulated OEM Paint

- Competitive Priced Production Paint

- Clean Air Formulas

- Less Fumes, Easy to Work With

- Not a Sticky Mess

- Utility Savings

- Reduce Solvent Usage

- Reduce Solvent Waste Stream

- Not a Fire Hazard

- Low VOC

- Available in Gallons, Pails, Drums & Totes

HIGH SOLIDS

Continental Products has developed a variety of high solids OEM paint in both primer and top coat formulas (bake and air dry) that provide heavy-duty performance. These production paints are used in a wide variety of applications for such diverse manufacturing industries as compressors, chillers, pumps, tractors, etc.

2K URETHANE

We are the pioneers of groundbreaking and industry leading OEM production paint. We specialize in ZERO VOC 2K Urethane OEM paint technology and DTM (Direct To Metal) 2K Urethane Primers.

REAL WORLD APPLICATIONS

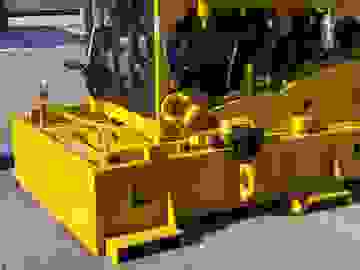

Pictured is a WATER BASED OEM Paint primer and water-based hybrid topcoat system being applied on production painted oil/gas field equipment.

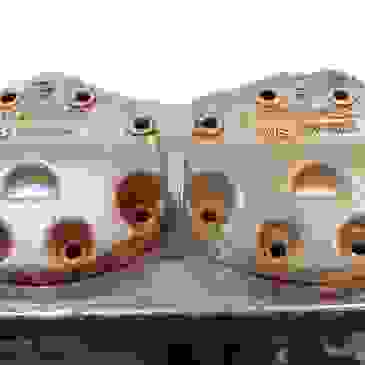

Pictured is a natural gas-line compressor made by a world leader of natural gas compressors that uses our special HIGH SOLIDS OEM paint electrostatic formula for all their compressors.

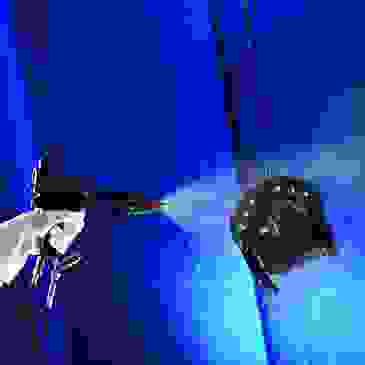

Pictured is a hooded space-suited production paint technician applying an exclusive ZERO VOC 2K URETHANE OEM paint onto the chassis of a truck.

R&D DESIGN PROCESS AND CRITERIA

CUSTOMER REQUIREMENTS

CUSTOMER REQUIREMENTS

CUSTOMER REQUIREMENTS

- Emissions

- Color & Gloss

- Dry Time

- Substrate

- Paint Line Parameters

- Corrosion Resistance

- Surface Characteristics

- Surface Hardness

- UV Resistance

- VOC

TESTING & EVALUATION

CUSTOMER REQUIREMENTS

CUSTOMER REQUIREMENTS

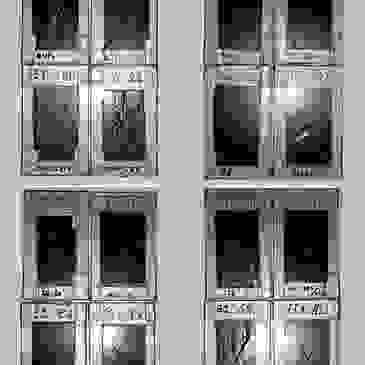

- Salt Spray

- QUV

- Humidity

- Stone Chip Resistance

- Adhesion

- Production Paint Impact

- Bend

- Fluid Immersion

- Heat Resistance

- OEM Paint Hardness

- UV Resistance

APPLICATION METHODS

CUSTOMER REQUIREMENTS

APPLICATION METHODS

- Conventional Spray Production Paint

- Electrostatic Spray Production Paint

- Dip

- Flow Coat OEM Paint

As well as adaptations to your particular application method.